Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: W600

Product Type: PVC Profile

Screw: Double-Screw

Automation: Automatic

Computerized: Non-Computerized

Certification: SGS

Customized: Customized

Packaging: film wrap and fixed in container

Transportation: Ocean

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

PVC Wall Panel Extrusion Line

Plastic UPVC/WPC/PVC (wood composite) Window/Ceiling/Wall Panel/Door Board/Flooring Sliding/Edge Banding/Corner Bead Profile Extrusion/Extruding Production Line

Plastic PE/PP/PVC/WPC Window Profile/Ceiling/Board/Wall Panel/Edge Banding/Sheet/ Pipe Extrusion Making Machinery

Brief Introduction:

This Line is used to produce all types of PVC window/door profiles, Wall/Ceiling panel profiles, Cable Trunking profiles, WPC profiles, and Imitation Marble profiles with changing the molds, like sliding frame, sliding frame case, fixing frame, fixing frame case, sliding leaf, sliding leaf frame, sliding gauze, sliding seal, single glass bead, double glass bead, sliding lid, door frame, etc.

If need, the co-extrusion is available as well.

All the electrical components are top quality, like SIEMENS, ABB, OMRON, SCHNEIDER, etc.

The Line has the feature of low waster of energy, good performance, high speed and high efficiency, etc.

The finished profiles produced by this machine has the feature of good surface, stronger compression resistance, light and heat stability, low size-changing and ageing resistance.

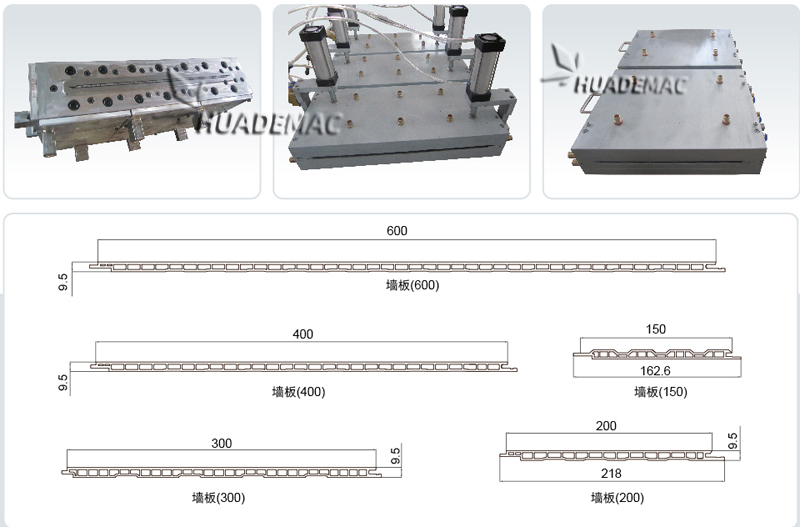

Usual size of panels:

Panel width: 180mm, 200mm, 250mm, 300mm, 400mm, 600mm, etc

Panel thickness: 4.5mm, 5.5mm, 6mm, 6.5mm, 7mm, 7.5mm, 8mm, 9mm, 10mm, 12mm, etc.

Technical Parameter:

| Applicable Width | 150-300mm | 400-600mm |

| Extruder | SJZ55/110 | SJZ65/132 |

| Motor Power(Kw) | 22 | 37 |

| Capacity(kg/h) | 200-250 | 250-300 |

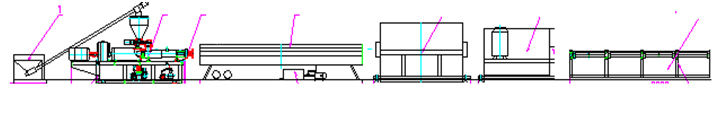

PVC wall panel production line process :

the screw feeder feed the raw materials to the mixer unit , after mix enough and the temperature reach the set temperature , the hot mixed raw materials will discharge into the cooling mixer automatically , then the spring feeder feed the mixed raw materials into the twin screw extruder , after plasticizing , extrusion and calibration , the profile will come out from the mould and follow into the cooling equipment , via the synchronous haul off machine , the profile enter the cutter , the cutter equip with the meter counter , it can cut different size according to the set length automatically .

Twin screw extruder

The PVC wall panel making machine equip with the conical twin screw extruder , converter control system , OMRON temperature control unit , it has wide control range , accuracy temperature control and easy to operate , the auxiliary equipment consist of vacuum calibration mould & platform, hauling off machine, hot stamping machine , cutting machine, stack machine ,etc.

World famous brand electrical component: Siemens, Schneider, ABB etc;

High torque gearbox with adopts NSK/SKF bearing;

Siemens original motor achieved global after service;

Bimetallic screw and barrel;

Simple PID automatic temperature control system

Die head

Material 3Cr17, it includes the die head parts, vacuum calibrator parts, water cooling tank parts

Vacuum calibration table

Durable stainless steel material make

Three dimensionall adjustable calibration table structure

Adopts powerful turbo cooling system, easy to achieve satisfactory cooling effect.

According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m or 6m.

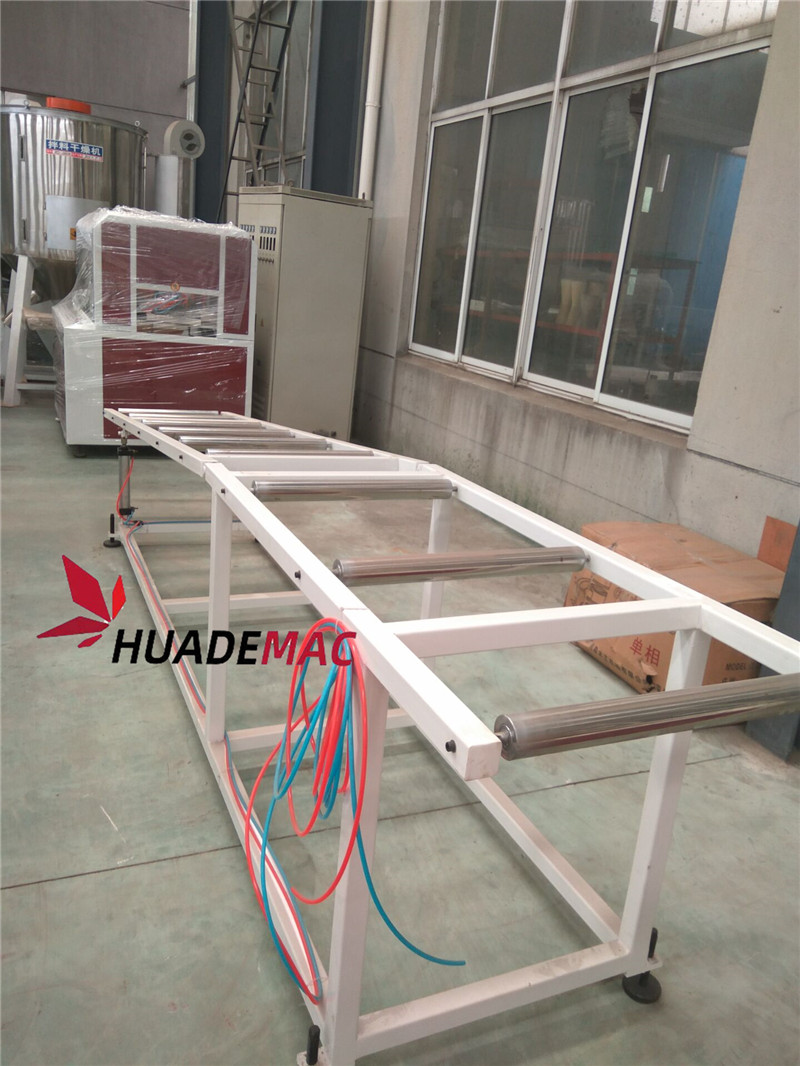

2 caterpillar haul off

Fast change type of silcone pads with aluminium support

Each caterpillar is driven independently by inverter.

Panel Cutter

Cutting machine speed is synchronized with hauling speed.

Swarfless cut structure ,good synchronization,precise length control,high quality cutting.

Stacking

Panel surface treatment device (hot stamping machine )

PVC wall panel and profile auxiliary equipment:

Product Categories : Plastic Profile Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.