Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 300-500

Transportation: Ocean

Port: SHANGHAI

Payment Type: L/C,T/T,D/P

Incoterm: FOB

Wet Plastic Pelletizing Machine

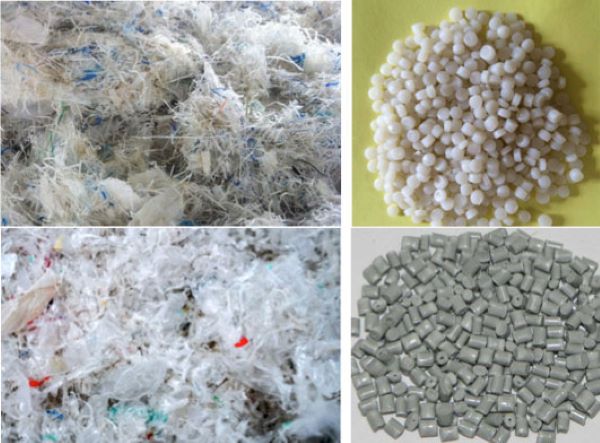

Our wet Plastic Pelletizing Line is applied to recycle wet PP/PE film and woven bag etc.the raw material moisture can accept less than 15%.

The unit consists of loading device, extruder, die head, screen exchanger,pellet cutter,dewatering machine,vibrating sieve and silo. The machine capacity is available for 200-1000kg per hour.

Realted Machine:

PP PE film/woven bag

1.Loadig device

Function :

to load wet plastic film into the extruder

Function :

melt plastic and exhaust waste air with degassing zones.

double stage can get more good quality final granules

3.Screen Exchanger

Function :

Filter out impurities

4.Die Head

Function :

Form plasticized plastic to a particular shape for follow-up process.

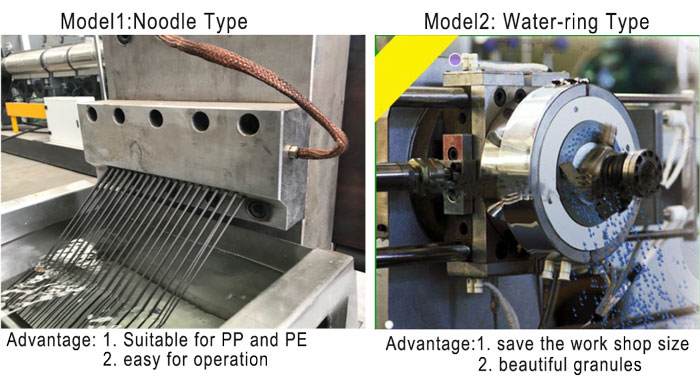

5.Pellet Cutting Machine

Water-ring type Cutting Device

Function :

Cut material out from die head to regular shape. Rinse to cool and shape up.

strand type cutting Device

Function:

Cut noodles to get regular plastic pellets.

6.Dewatering Machine

Water-ring type Cutting Device

Function :

Remove water by centrifugal force

7.Vibrating Sieve Air Blower And Silo

Water-ring type Cutting Device

Function :

Select right sized plastic granules,air blower and silo is for granules storage

Packaging&Exhibition

Product Categories : Plastic Recycling Granulating Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.