Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SJSZ80/156

Screw No.: Double-screw

Automation: Automatic

Computerized: Computerized

Certification: ISO9001:2008

Customized: Customized

Condition: New

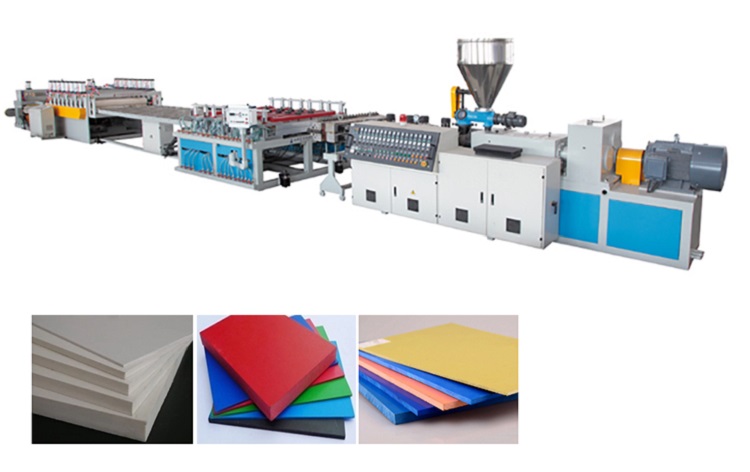

Name: PVC Foam Board Extrusion Making Machine

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

PVC foam board extrusion making machine

Machine line Features:

It combines advanced, reliability and practicality as a whole, reasonable structure, superior performance may be comparable to similar foreign advanced equipment for production of 3-30mm thick, high-quality color PVC foam board.

Application:

1. Such as building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust room board, ceiling plate, etc.

2. Such as screen printing, computer lettering, ad board, etc.

3. cabinet board, chemical industry antisepticizing project, thermoforming for refrigerator, for temperature keeping for environment protection, etc.

4. Such as steamship, aeroplane, carriage, train compartment, roof shed, case core layer, inner upholster, etc.

Eletrical Parts:

1. Main motor frequency controller : simens or ABB

2. Temperature controller : OMRON or RKC

3. AC controller : Schneider or simens

4. Thermal overload relay : Schneider

5. Switch : DELIXI or Schneider

| Advertising application | |||

| Production width | 1220mm | 1560mm | 2050mm |

| Production thickness | 2-10mm | 5-20mm | 2-18mm |

| Extruder model | SJZ80/156 | SJZ80/156 | SJZ80/156 |

| Capacity(Max) | 300kg/h | 400kg/h | 400kg/h |

| Main motor power | 75kw | 75kw | 75kw |

| Door application | |||

| Production width | 900mm | 820mm | 760mm |

| Production thickness | 20-35mm | 20-35mm | 20-35mm |

| Extruder model | SJZ80/173 | SJZ80/173 | SJZ80/173 |

| Capacity(Max) | 450kg/h | 450kg/h | 450kg/h |

| Main motor power | 90kw | 90kw | 90kw |

PVC foam board extrusion making machine process

PVC foam board extrusion making machine photos

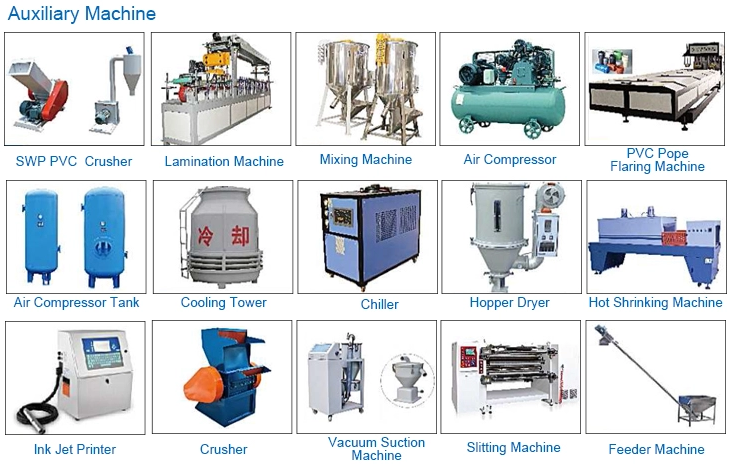

Other products

Packaging of PVC foam board extrusion making machine

Certification of PVC foam board extrusion making machine

Zhangjiagang Huade Machinery

Product Categories : Plastic Board Sheet Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.