Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HD300

Brand: huade

Application: Profile

Processing Plastic Type: Pe, Pp

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Philippines, Saudi Arabia, Argentina

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Competitive Price

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): United States, Peru, Saudi Arabia, Morocco

Applicable Industry: Building Material Shops, Manufacturing Plant, Restaurant, Construction Works

Marketing Type: Hot Product 2019

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Screw

Packaging: film wrap and fixed in container

Productivity: 80-120KG/H

Transportation: Ocean

Place of Origin: china

Supply Ability: 10set per month

Certificate: CE

HS Code: 84778000

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

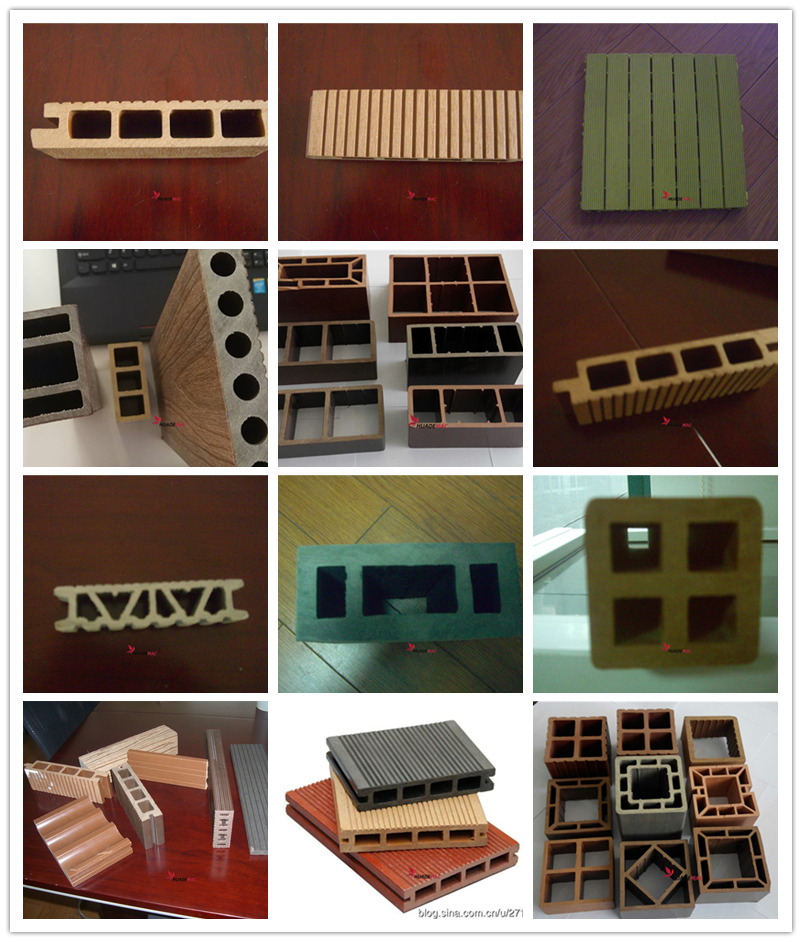

The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 65%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

| Model | HD180 | HD240 | HD300 | HD400 |

| Max width of product (mm) | 180 | 240 | 300 | 400 |

| Extruder model | SJSZ55/110 | SJSZ65/132 | SJSZ65/132 | SJSZ65/132 |

| Max extrusion Capacity (kg/hr) | 150 | 250 | 250 | 250 |

| Extruder power (KW) | 22 | 30/37KW | 30/37KW | 30/37KW |

| Cooling water (m3/hr) | 5 | 7 | 7 | 8 |

Product Categories : WPC Extrusion Machine

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.