Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 315-630mm

Brand: huade

Application: Pipe

Processing Plastic Type: Pe, Pp

Status: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): Other

Screw Length To Diameter Ratio: 188:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, Russia, South Korea, Colombia

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Multifunctional

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Germany, Spain, Argentina, South Korea, Sri Lanka

Applicable Industry: Manufacturing Plant, Construction Works

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gearbox

Productivity: 800

Transportation: Ocean

Place of Origin: china

Supply Ability: 10

Certificate: ce

HS Code: 84778000

Port: shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Diameter Range (mm): 315 355 400 500 560 630 wall thickness by request

Main Extruder Motor Power: 110kw

Line Space Occupation: 35mx4mx3m

Capacity: 600-800kg/h

Details Images

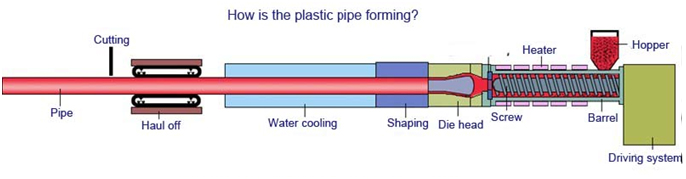

Conical twin screw extruder or parallel twin screw extruder can be applied to produce PVC pipe.With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

Motor power: 110KW

World famous brand electrical component such as Siemens, Schneider, ABB etc;

High torque gearbox with adopts NSK/SKF bearing;

Siemens original motor achieved global after service;

Bimetallic screw and barrel;

Extrusion die head apply bracket structure, each material flow channel is placed evenly.

Each channel after heat treatment, mirror polishing and chroming to ensure material flow smoothly.

Die head is modular design,easy for changing pipe sizes, assembling, dismantle and maintenance.

Vacuum calibration tank is used to shape and cool pipe, so as to reach standard pipe size.

We use double-chamberstructure.First chamber in short length, to ensure very strong cooling and vacuum function.

As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better

forming and coolingof pipe.

6 Caterpillar Haul off unit provides sufficient traction force to pull pipe stably.

According to different pipe sizes and thickness,our company will customize traction speed, number of claws, effective traction length.

To ensure matchpipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

Planetary Cutter controlled by Siemens PLC, working together with haul off unit to have precise cutting.

Customer can set the length of pipe they want to cut.Multi-feed-in actions for the accomplishment of one cutting process

(protect blades and saws, prevent from blade and saws stuck for thick pipe and cut face of pipe is smooth).

PVC on-line belling machine to make socket at pipe end which is easy for pipe connection.

There are three types of belling type: U type, R type and Square type.

Product Categories : PVC Large Diameter Pipe Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.